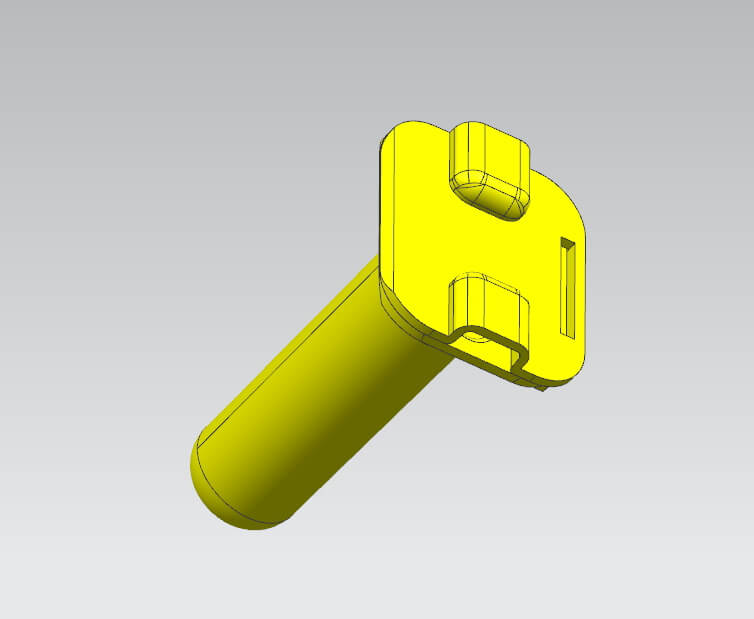

*Developed a replacement connector for existing fencing systems.

*Ensured sealing and waterproofing, with a focus on low cost and high production capacity.

The client, a distributor in the pet industry, sought to expand their brand by introducing a replacement connector compatible with existing fencing systems. The connector needed to meet the specific requirements of sealing, waterproofing, and cost-effectiveness.

The client needed a connector designed to be compatible with existing fencing systems, with a focus on low cost, sealing, and waterproofing. The connector also needed to meet high production capacity demands.

*Designed a custom ID for the connector to support the client's brand expansion goals.

*Created and optimized molds for efficient in-house production.

*Conducted multiple rounds of material and prototype testing to ensure quality and functionality.

We completed development to mass production in approximately 40 days. The connector went into mass production smoothly after multiple rounds of material and prototype confirmations.

Our collaboration led to the successful development and production of a market-ready replacement connector. This project showcases our ability to deliver innovative, high-quality products efficiently, supporting the client's brand and market expansion goals.

Maximize the value of cooperation by our efforts Make collaboration

sustainable to your needs